The cost of almost everything is soaring these days. Heating your business will be no exception come winter. The Winter Fuels Outlook from the US Energy Information Administration predicts spending will increase for all heating fuels this winter (October through March). Propane users can expect to pay 5% more, while electricity users can expect to pay 10% more. However, businesses that rely on natural gas for heat should brace themselves for the steepest increase in costs.

The EIA forecasts natural gas users will pay up to 28% more for heat this winter than last. The natural gas spot price was already more than double in August 2022 than it was in August 2021, going from 4.07 dollars per million btu to 8.81 dollars per million btu. Considering that average natural gas spot price in August for any given year between 2016-2020 has been 2.64 dollars per million btu, 8.81 dollars per million btu is quite a steep jump.

In fact, we haven’t seen natural gas spot prices that high since the financial crash of 2008. Unfortunately, these prices are likely to keep surging as coal plant shutdowns increase the demand for natural gas to generate power. That is a very unwelcoming statistic in an economy where inflation is rising.

However, there is an economical energy source alternative that can vastly reduce your energy bill this winter: a waste oil heater.

If your company produces waste oil, it’s worth considering how a waste oil heater can provide efficient heat, reduce winter energy bills, and diminish your cradle-to-grave liability.

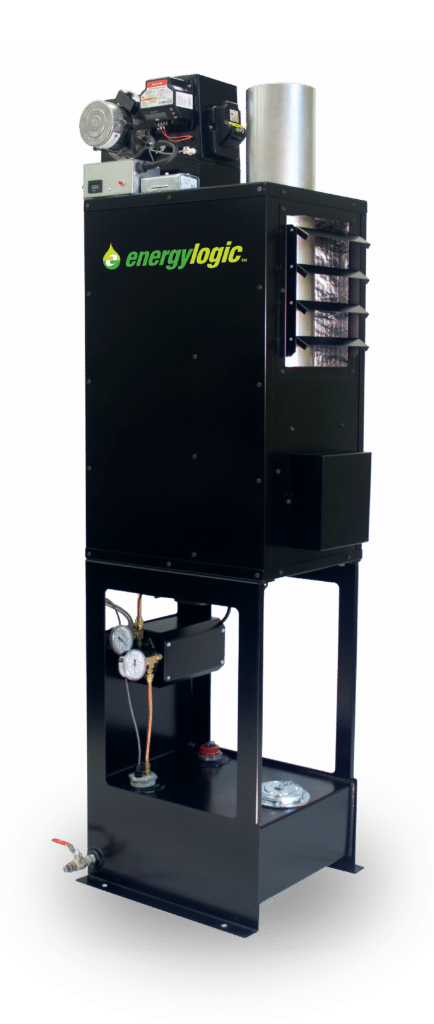

Modern Waste Oil Heaters

Waste oil heaters have come a long way from the dirty, smelly, and hard-to-clean systems of the past. Modern waste oil heaters can burn various used oils efficiently, safely, and cleanly.

Thanks to technological advances, modern waste oil burners create a high heat output with very little ash accumulation. For instance, the American-made Beckett chassis used by EnergyLogic produces a burner flame of 1,500+ degrees. It also has a heat output of 120 degrees above room temperature. With such a superior flame, modern waste oil burners can incinerate more impurities that cause ash. This makes cleaning easy. Furthermore, today’s heaters can process a wide range of used and waste oils from No. 2 to 90W, including synthetics.

These 21st-century features make today’s waste oil heaters a reliable, clean-burning option for fuel recovery.

Waste Oil Heaters Deliver Free Heat

In the past, producers of used oil could get paid to have their waste oil hauled off. This is no longer the case. Most waste oil producers must invest time and dollars in properly collecting, storing, and disposing of used oil. This can add up to considerable costs and liabilities.

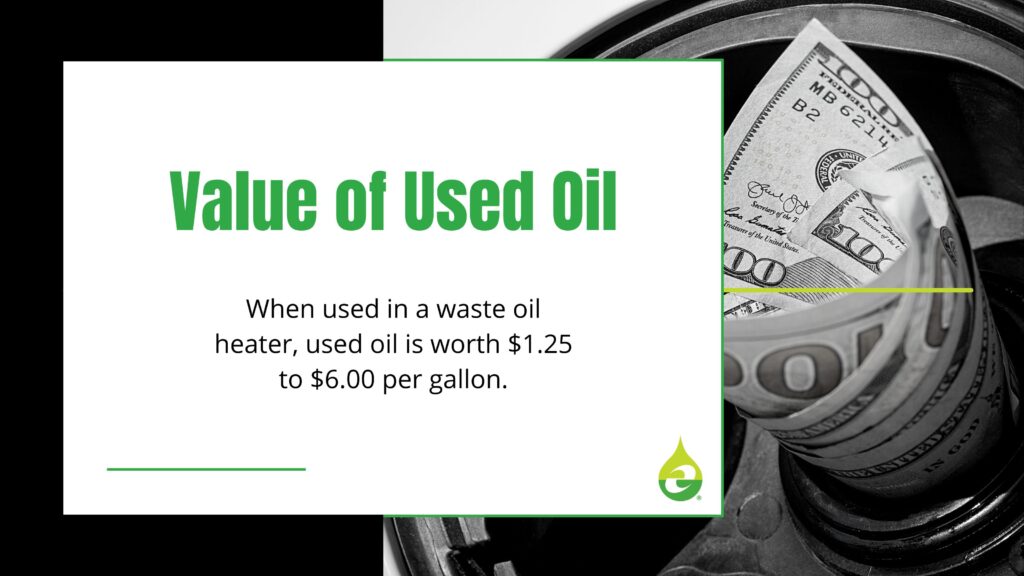

Keeping the waste oil on site not only reduces removal costs and liabilities, but it can provide free fuel for heat. Used oil has valuable energy that can be taken right out of a vehicle and immediately used to power a furnace. Just one gallon of used oil contains a similar amount of available energy as a gallon of #2 heating oil (approximately 140 kBTU/gallon or 41 kW/hr). That’s almost one and a half thermos of natural gas. When used in a waste oil heater, used oil is worth $1.25 to $6.00 per gallon, depending on the fuel source it is replacing. Not only that, one gallon of waste oil can heat a 3,500-square-foot facility with 16-foot ceilings for an hour.

With natural gas and electricity rising, it’s easy to see how even a small automotive repair shop can save thousands of dollars a year on energy costs. For example, consider a 3,900 square foot facility that generates approximately 140 gallons of used oil monthly. A waste oil heater can save this facility around $3,500 annually compared to heating with natural gas. That is a 10-year savings of over $27,000 after subtracting the equipment cost.

Waste Oil Heaters Are Also Tax-Deductible

Under Section 179 of the IRS Tax Code, waste oil heaters are tax-deductible. In short, Section 179 of the IRS Tax Code allows business taxpayers to deduct the entire cost of qualifying equipment (up to $1,040,000 for 2020) from their tax return. Qualifying equipment includes waste oil heaters.

Therefore, purchasing a waste oil heater for the first time can add further winter fuel savings to a business by reducing its taxes: a win-win.

Which Businesses Can Save the Most by Installing a Waste Oil Heater?

Any business that accumulates used motor oil as part of their daily operations can substantially reduce winter energy bills by installing a waste oil heater.

The type of business you operate and how much oil you generate will determine your potential savings. However, any company that generates waste oil consistently is an ideal candidate for a waste oil heater installation.

Some of the most common industries and applications for waste oil heating systems include:

· Agricultural & Equestrian

· Automotive & Fleet Management

· Aviation & Transportation

· Commercial & Hospitality

· Education & Municipal

· Sports & Fitness

· Industrial & Heavy Equipment

Find Out How Quickly an EnergyLogic Waste Oil Heater Can Pay for Itself in Your Workspace

Waste oil collection fees and raising heating bills substantially affect a business’s bottom line. Cradle-to-grave liability also adds to operating costs. However, installing a waste oil burner in your workspace can reduce these expenses. And, most waste oil heaters usually pay for themselves in one to two years.

EnergyLogic’s Waste Oil Calculator can provide an instant estimate of your facility’s potential energy bill savings this winter.

Alternatively, to get a no-obligation custom quote on how quickly a waste oil heater can pay for itself in your workplace, contact EnergyLogic today.