Oil fuels our cars, runs our machinery and heats our homes. Oil is even used to create a wide range of products, such as propane, asphalt, and petrochemical feedstock which gets turned into plastic. Although oil is essential in our modern society, these industrial processes create an inevitable by-product: waste oil.

Properly disposing waste oil is a legal requirement with strict regulations set out by the Environmental Protection Agency (EPA). While approved methods of disposal keep millions of gallons of waste oil from polluting our environment each year, it can also put a considerable drain on a business’ bottom line. Increasingly, industries must pay to have waste oil hauled off site and properly disposed. Cradle-to-grave liability adds another financial burden and worry.

Fortunately, the future is looking bright when it comes to waste oil. As technology continues to advance, we now have alternative uses for this material that avoids a costly removal and disastrous environmental consequences.

Understanding Waste Oil

Waste oil is generally defined as any type of refined crude oil or synthetic oil that can no longer perform its intended use. Oils are used for a variety of industrial and manufacturing processes such as lubrication, hydraulics, buoyancy, and heat transfer. Through these uses thermal breakdown occurs and contaminants, like sawdust, dirt, dust, metal shavings, and salt, gradually accumulate in the oils.

Although waste oil has been contaminated, it can still be collected, refined, recycled, and used again. So instead of ending up in a landfill or in our waterways, waste oil can be used for other industrial processes and as an innovative energy source.

Recycling Waste Oil

Recycling waste oil is like doing laundry: you remove the dirty particles so it can be used again. After oil has been used and contaminated, it can go through a variety of processes to filter, clean, and recycle the oil so that it can be reused. Recycling waste oil is a broad label that can refer to many different processes and end uses.

Some facilities will recondition their waste oil on-site and use it again immediately. This process uses a filtering system to remove impurities at the site where the oil was used, a useful method for large operations that generate a lot of waste oil. However, most of the methods used to do this on-site don’t completely renew the oil, but rather extend its effective lifespan.

Another form of recycling waste oil is re-refining. Any vehicle maintenance facility or machinery maintenance operations that uses oil can also use re-refined oil. In this process, the waste oil is dewatered, distilled and hydro-treated to remove contaminants and impurities then used as a base for new oil. The resulting product is virtually identical to virgin oil, thus can reduce the amount of new oil that a company must purchase.

Additionally, used oil can be fed into the front end of a petroleum refining process to produce gasoline.

Whatever the method, recycling used oil is preferable to disposal. Recycling waste oil reduces resource expenses and operating costs, mitigates negative impacts on the environment, and encourages more sustainable energy solutions.

Capturing the Value of Waste Oil as Fuel

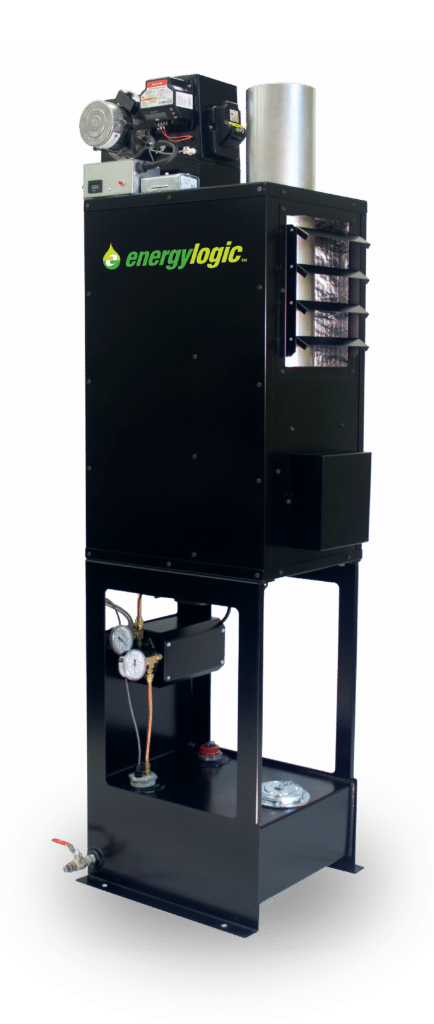

An additional method of recycling waste oil, and one of the most cost effective for businesses, is processing it and burning it for energy recovery. In this process, the oil is filtered to remove water and contaminants and then burned to make heat or power for industrial operations. This method is one of the best ways modern companies are recycling used oil.

Almost every kind of oil can be repurposed as fuel—from motor oil to emu oil—and these oils can fuel heating systems or the evaporators used in water/oil separators, effectively creating an in-house recycling process for turning waste into energy. Additionally, using waste oil as a combustion agent for a heating apparatus, means an enterprise isn’t paying a utility company to keep its facility warm.

Although a facility must invest in a waste oil heater and boiler to use waste oil as fuel, the costs can pay for themselves within a year. Not only are utility costs reduced, but cradle-to-grave liability is minimized. Cradle-to-grave liability refers to the responsibility of the waste oil producer to ensure the waste oil is disposed of properly or risk large fines. This rule even applies when the business pays to have the oil collected, the liability does not transfer to the waste oil collector.

With a waste oil heater or boiler, gone is the worry, cost, and complex processes for properly disposing of waste oils. For these reasons, many companies find that using waste oil as fuel is a cost-effective and responsible method for handling waste oils.

Develop a Unique Solution for Your Company

Unfortunately, according to the EPA, two hundred million gallons of used oil are improperly disposed of each year in the United States alone. If more companies pursued sustainable and responsible oil handling processes, they would reduce the negative impact their operations have on the environment while reaping tangible benefits, like reduced costs and improved productivity.

At Energy Logic, we understand the importance of reducing a business’s environmental impact without negatively impacting the bottom line. We also understand that every enterprise from every industry has unique concerns, processes, and types of oils used in its operations. That is why we offer tailored solutions to all our clients.

If you’re interested in pursuing a more sustainable energy plan for your company, reducing your overhead, and improving your production efficacy, consider how to use your waste oils as a beneficial source of energy and savings. Reach out to us to set up an oil test, and we can help you develop a solution that works best for your organization.