The rising costs of energy and environmental concerns have made many business owners reconsider their heating options, especially when they are heating large spaces for long periods of time. One way to heat these spaces is with a waste oil furnace or an electric furnace. And, while waste oil furnaces are not new, they have undergone significant advances since their inception, burning cleaner and hotter than ever before. In this blog, we will walk you through the differences between waste oil furnaces, oil furnaces, electric furnaces, and natural gas furnaces, their contributions to energy efficiency, and which is best for your space and budget.

Understanding Waste Oil Furnaces

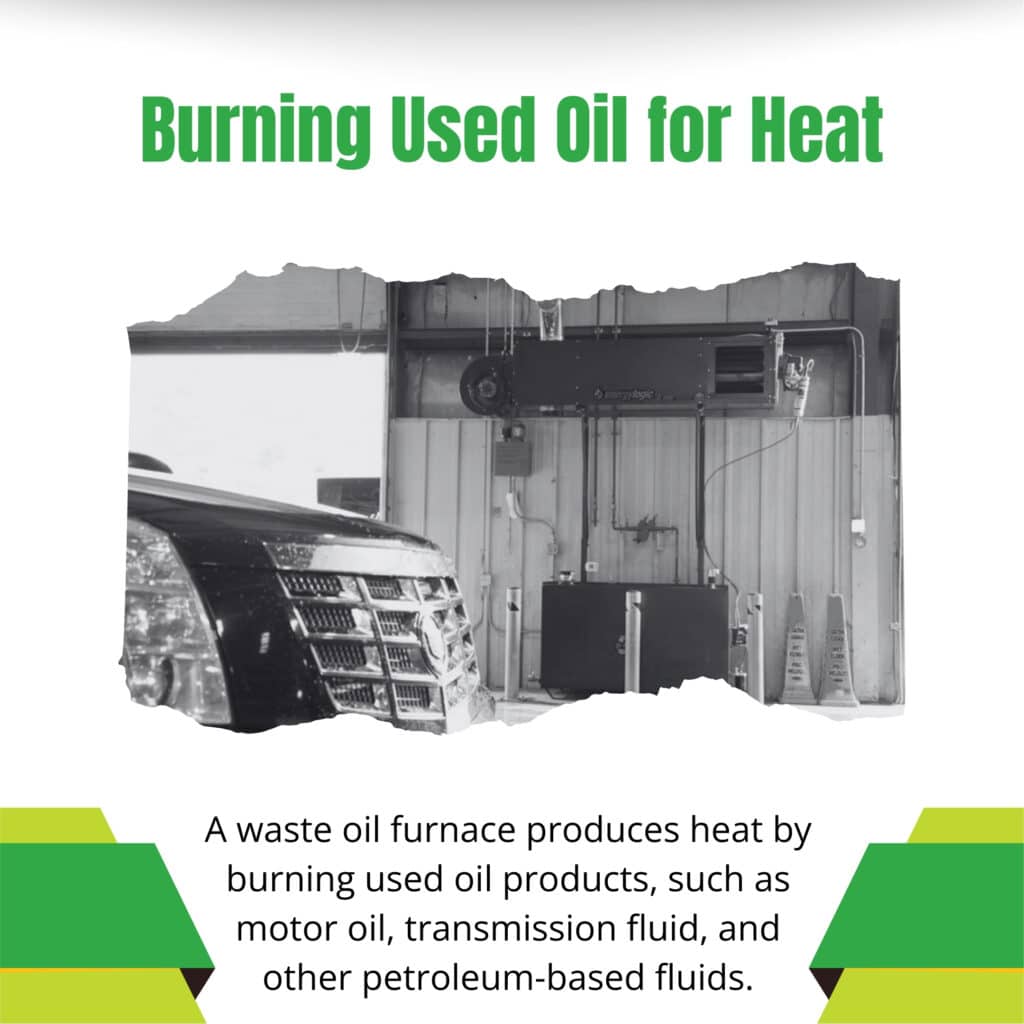

A waste oil furnace produces heat by burning used oil products, such as motor oil, transmission fluid, and other petroleum-based fluids. These furnaces are often used in commercial settings like auto repair shops, manufacturing plants, and other industries where large quantities of waste oil are generated. Waste oil is considered hazardous waste, and companies that produce it are responsible for disposing of it properly. If they are not burning the waste oil in an EPA-approved waste oil furnace, most likely the company is paying someone to haul it away. Unfortunately, this costs money and holds the waste-oil generator liable for environmental contamination should the hauler have trouble.

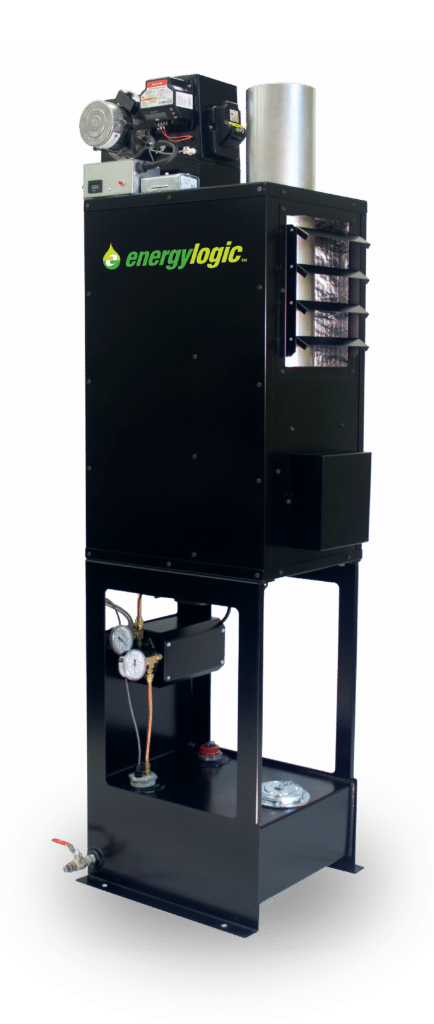

Waste oil furnaces operate by converting used oil into heat through a controlled combustion process.

- Collection and storage: First, the waste oil is collected and stored in a waste oil tank connected to the furnace. Oils approved for use in an EnergyLogic waste oil furnace include: used crankcase oil (not new!), used automatic transmission fluid, and ASTM D396 No. 2 Fuel Oil (Diesel Fuel)

- Pre-heating: Before combustion, the waste oil is preheated to reduce its viscosity. This is crucial because waste oils are often thicker than traditional heating fuels. Preheating ensures the oil flows smoothly through the system and burns efficiently.

- Atomization: The preheated oil is then atomized, which means it is broken down into tiny droplets. This is done using compressed air. Atomization allows the oil to mix more effectively with air, leading to more efficient combustion.

- Combustion Process: The atomized oil is ignited in the furnace’s combustion chamber. The resulting flame heats a heat exchanger, which transfers the heat to air or water, depending on the furnace design. This heated air or water is then distributed throughout the building to provide warmth.

- Exhaust and Emissions: EnergyLogic’s waste oil furnaces are designed to burn oil cleanly. The exhaust gases are vented out through a chimney or flue, similar to traditional furnaces.

Understanding Traditional Furnaces

Traditional furnaces have been the cornerstone of residential and commercial heating for decades. They work by drawing in cold air, warming it, and distributing the heated air throughout the space.

The most common types include:

- Oil-Burning Furnaces: These are powered by heating oil, which is burned to produce heat. Oil-burning furnaces are popular in areas where natural gas isn’t readily available. They are known for their ability to produce significant heat, even in the coldest climates. Similar to a waste oil furnace, an oil-burning furnace will pump oil from a storage tank into the burner, where it is atomized and mixed with air. The mixture is then ignited to heat the heat exchanger. The heat exchanger transfers the generated heat to the air, which is then blown through ducts and distributed.

- Natural Gas Furnaces: These are perhaps the most widespread type of furnace, particularly in urban areas. Natural gas furnaces are efficient and typically require less maintenance than traditional oil-burning furnaces.

- Electric Furnaces: Electric furnaces convert electricity into heat using heating elements. While generally less efficient than gas or oil furnaces, electric furnaces are often chosen for their simplicity, lower upfront costs, and safety, as they don’t involve combustion. Electric furnaces work by using resistance heating, flowing electric currents through coils or elements to generate heat. A blower fan moves air over the heated coils, and the warm air is then distributed through the ductwork to the living spaces.

Comparing Operating Costs: Oil Cost vs Electric Cost

When deciding between an oil-burning furnace and an electric furnace, one of the most critical factors to consider is the ongoing cost of operation. Consider the following costs:

- Waste Oil Costs: Since EnergyLogic’s heaters are waste oil burning, oil prices do not really matter in this scenario. As a generator of waste oil, you would be saving money to burn your waste oil instead of paying a company to haul it away. With regular oil furnaces, the cost of oil will depend on the market and your location. Heating oil prices can fluctuate based on market conditions, supply and demand, and geopolitical factors.

- Electric Costs: Electric furnaces tend to have lower initial installation costs, but they can be more expensive to operate. Electricity rates are usually more stable than oil prices, but the cost per BTU of heat generated by electricity is generally higher than that of oil. This can lead to higher energy bills, particularly in regions with high electricity rates. Hawaii has the highest electricity cost at $.44 per kilowatt-hour and Utah boasts the lowest at $.11 per kilowatt-hour.

- Natural gas or propane prices: Last year, in 2023, natural gas prices were low due to a warmer-than-expected winter season and a high supply. However, the Energy Information Association is predicting that November-March 2024 is going to be different with demand outpacing supply, resulting in higher prices across the country as drillers and producers struggle to keep up with residences and businesses.

Energy Efficiency

Efficiency is another crucial factor that influences the overall cost of running a furnace. Here’s a breakdown of the efficiency considerations:

Oil-Burning Furnaces: Oil furnaces typically have an Annual Fuel Utilization Efficiency (AFUE) rating between 80% and 90%. Higher AFUE ratings indicate greater efficiency, meaning more of the oil’s energy is converted into heat. While oil furnaces can be efficient, the cost savings may be offset if oil prices rise significantly. Additionally, older oil furnaces tend to be less efficient, which can increase fuel costs over time.

Electric Furnaces: Electric furnaces are nearly 100% efficient in converting electricity to heat since there’s no combustion process. However, the efficiency of electric heating can be diminished if the electricity is generated from non-renewable sources. Despite their high efficiency, the higher cost of electricity can lead to higher overall heating costs compared to oil, especially in areas where electricity rates are high.

What is Furnace Waste Oil?

Furnace waste oil refers to used oil that can be repurposed as fuel for waste oil furnaces. This oil comes from a variety of sources, including:

- Automotive Oil: Used motor oil from cars, trucks, and machinery is one of the most common types of waste oil. It includes engine oil, transmission fluid, and other lubricants.

- Industrial Oil: Industries that use heavy machinery often produce waste oils, such as hydraulic fluids, cutting oils, and gear oils.

Benefits of Using Waste Oil as Fuel

Using waste oil as a fuel source offers several advantages, particularly for businesses and organizations that generate or have access to large quantities of used oil:

- Cost-Effectiveness: One of the most significant benefits is the cost savings associated with using waste oil. Since waste oil is often available at little to no cost, using it as fuel can drastically reduce heating expenses, especially compared to purchasing traditional heating fuels.

- Environmental Impact: Recycling waste oil into fuel reduces the need for oil disposal, which can be both costly and environmentally harmful. By burning waste oil in a controlled environment, users can prevent potential contamination of soil and water and reduce the carbon footprint associated with heating.

- Waste Reduction: Using waste oil as fuel helps reduce the overall amount of waste generated, contributing to a more sustainable operation. This is particularly beneficial for industries that produce large quantities of waste oil, as it turns a potential liability into an asset.

Challenges of Waste Oil Furnaces

While waste oil furnaces offer many benefits, there are also challenges to consider:

- Regulatory and Maintenance Requirements: Waste oil furnaces are subject to strict regulations due to the potential environmental impact. Users must comply with local, state, and federal regulations, which can involve regular inspections and permits. Additionally, waste oil furnaces require more frequent maintenance compared to traditional furnaces to ensure efficient and safe operation.

- Availability of Waste Oil: Not all users have ready access to sufficient waste oil. For businesses that do not generate enough waste oil on their own, securing a consistent supply may involve additional logistics and costs.

- Initial Investment: Waste oil furnaces generally require a higher upfront investment than traditional furnaces. However, this can be offset by long-term fuel savings, depending on the availability and cost of waste oil.

Which Furnace is Right for You?

Choosing between a waste oil furnace and a traditional furnace depends on various factors unique to your situation:

- Budget and Long-Term Cost Projections: Consider both the initial installation cost and the ongoing operating costs. If you have access to a steady supply of waste oil, a waste oil furnace could offer significant long-term savings. However, if fuel costs or availability are uncertain, a traditional furnace might provide more predictable expenses.

- Availability of Fuel Sources: The practicality of a waste oil furnace largely depends on your ability to secure a consistent supply of waste oil. If you generate waste oil as part of your operations or can easily source it, this option may be highly beneficial. If not, a traditional oil or gas furnace may be a more convenient and reliable option.

Check out EnergyLogic’s waste oil furnaces and boilers or contact our team to get help customizing a complete system for your space.