Burning waste oil can offer several benefits when done responsibly and efficiently. For one, burning waste oil is an environmentally friendly alternative to disposing of it in landfills.

Additionally, burning waste oil can convert a waste product into useful energy in the form of heat or electricity. This energy can be used for various purposes, including space heating, hot water production, process heating, and even electricity generation. In turn, utilizing waste oil as a fuel source can lead to significant cost savings, especially for businesses or facilities that generate substantial quantities of waste oil.

But where does waste oil come from, and how does it produce energy? Here is a detailed guide to how waste oil is generated and transformed into heat.

Generating Waste Oil

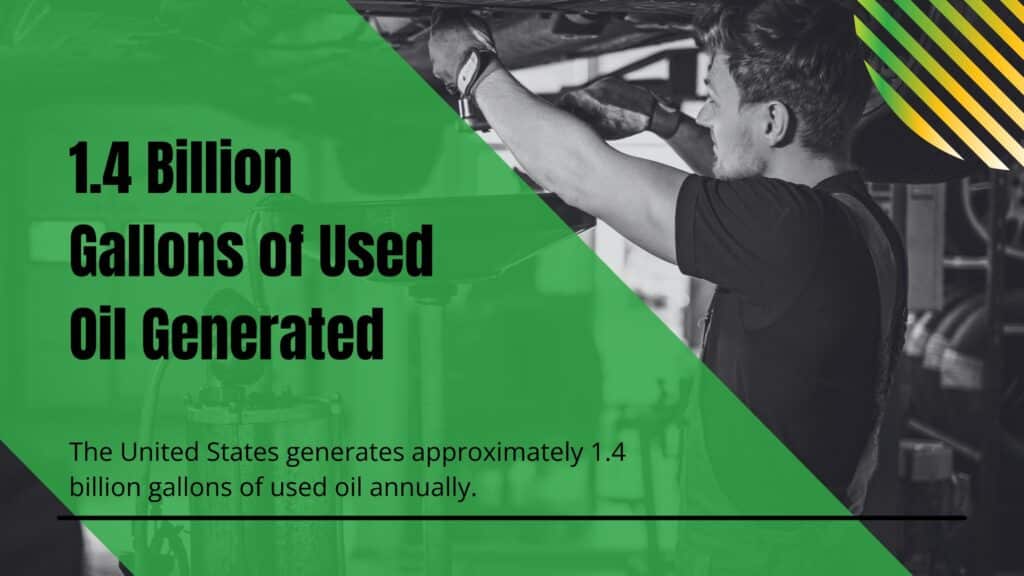

The journey of waste oil to warmth begins with the creation of waste oil. Waste oil, or used oil, is produced when any petroleum-based or synthetic oil becomes unsuitable for its original purpose due to contamination. Consider vehicle engines. As car, truck, motorcycle, and boat engines operate, the motor oil inside them wears out and becomes contaminated over time. This motor oil is typically replaced every couple of months through oil changes. The used motor oil that is drained out is considered waste oil.

Another example is industrial machinery. Many industrial processes rely on lubricating oils, hydraulic fluids, and other oil-based products to keep machinery and equipment running smoothly. Over time, these oils can become contaminated with particulates, heat, and chemical by-products. And just like motor oil, it needs to be replaced or changed periodically. Leading to the generation of more waste oil.

Through these processes and others, the United States generates approximately 1.4 billion gallons of used oil annually. All that waste oil has to go somewhere!

Luckily, waste oil that is properly collected, stored, managed, and processed can have lots of value.

Collecting and Storing Waste Oil Properly

If you collect used motor oil as a shop owner or manage waste oil in an industrial setting, proper waste oil collection and storage is vital, and legally required. Proper waste oil collection and storage not only protects the environment, but it also ensures that waste oil is viable for recycling, re-refining, reuse, and energy recovery. Here are some key collection and storage processes to consider if you want to turn your waste oil into heat:

- Follow Regulations: There are numerous federal, state, and local regulations regarding the collection and storage of waste oil. Being aware of and complying with these regulations is critical to protecting the environment.

- Prevent Spills: When draining used motor oil from a vehicle or machinery, use a funnel or drip pan to catch any spills. Place absorbent materials, such as oil absorbent pads or kitty litter, around the collection area to quickly soak up any accidental spills.

- Select Specifically Designed Waste Oil Storage Tanks: Waste oil should be collected and stored in waste oil tanks specifically designed for storing waste oil. Such tanks should be made of materials that are compatible with oil and have secure lids to prevent spills and contamination. Using specifically designed waste oil storage tanks can also make preparing waste oil to heat easier. For example, Energy Logic waste oil storage tanks have an elevated fuel pickup to allow impurities to settle to the bottom of the storage tank which leads to a clean burn. Waste oil storage tanks can also come with a low fuel cutoff valve to turn off a waste oil burner system before it becomes problematic. Additionally, using a waste oil storage tank with an integrated drain value can help to easily clean sludge, antifreeze, and other contaminants that settle at the bottom of the tank.

- Label Containers: All waste oil storage containers must be clearly labelled with the words ‘Used Oil’ or a similar designation. This helps prevent confusion and ensures that people handling the containers know their contents.

- Properly Store and Maintain Containers: Waste oil containers should be stored in a designated area away from rain and other potential contaminants. Additionally, containers should be kept tightly sealed to prevent leaks or spills. Outdoor tanks should be properly maintained and inspected for leaks.

- Maintain Cleanliness: Keep the area around the waste oil collection containers clean and free of debris to prevent contamination. Avoid mixing waste oil with other substances, such as water or solvents, as this can make recycling more challenging.

- Keep Accurate Records: Maintain records of waste oil collection and disposal activities, including the volume of waste oil generated and collection dates. Proper documentation can be essential for compliance and reporting purposes.

Refining Waste Oil

Before used oil can be burned for heat, it may undergo some preparatory steps to remove impurities and contaminants. This can include filtering or centrifuging the oil to remove debris and water, as well as treating it to reduce harmful chemicals or pollutants.

Installing a Waste Oil Burner

Properly collected and stored waste oil can be used for energy recovery. Specially designed equipment can safely and efficiently combust waste oil to generate heat or electricity. Here are some items to consider when installing a waste oil burner:

Select Specially Designed Equipment:

- Choose and install a waste oil burner or boiler that is specifically designed for burning waste oil. Specialty systems are equipped with features to handle the unique characteristics of waste oil, such as impurities and varying viscosity. Specially designed equipment for burning waste oil provides a safer and cleaner burn.

- Choose a UOMA Member Heater: The Used Oil Management Association ensures its members have their heater and boiler units tested for safety by independent laboratories such as Underwriters’ Laboratories (UL) and the Canadian Standards Association (CSA), and each used-oil heater and boiler comes with a safety rating. This ensures that all UOMA Member used-oil heaters and boilers function safely, cleanly, and efficiently.

- Consider Available Features: Modern waste oil burners and boilers are equipped with sophisticated features that monitor and adjust combustion parameters, such as air-to-fuel ratios and temperature. These features help optimize efficiency and minimize emissions for a cleaner and more efficient burn. Some specific features to look out for include:

- A Stainless-Steel Heat Exchanger: To prevent corrosion, warping, and weld breakage.

- Accutemp Preheater: To rapidly heat the widest range of viscosities of used oil, synthetic oils, and other acceptable fuels.

- Integrated Air Compressor: Meaning you don’t have to connect to and rely on shop air. Providing 24/7 heating availability.

- Swing Away Burner: To make cleaning the chamber faster and easier with one tool in 30 minutes or less.

- Flame Retention Head: To create a hotter flame for complete fuel combustion and the highest heat output. Additionally, it produces less ash, reducing maintenance intervals.

Add Valuable Accessories: Waste oil burner accessories can help customize a waste oil heater to meet your exact needs. Some accessories you may want to consider include:

- Furnace wall brackets

- Low-fuel cut-off switches

- Transfer pump

- Cleaning materials

Combusting Waste Oil to Generate Warmth

Just collecting waste oil and installing a waste oil heater isn’t enough to generate warmth from used oil. For the hottest burn, you need proper combustion.

Combustion is a chemical reaction that occurs when a fuel, in this case, used oil, reacts with oxygen (usually from the air) in the presence of heat or an ignition source. This process releases energy in the form of heat and light.

It begins with cleaned and prepared used oil being introduced into a combustion chamber. This chamber is designed to mix the oil with air (containing oxygen) in precise proportions to support combustion.

Next, an ignition source, such as a spark plug or a heating element, is used to initiate the combustion process. This source provides the initial heat needed to start the chemical reaction.

Once ignited, the used oil vaporizes and breaks down into smaller molecules due to the high temperature. The chemical reaction between these vaporized hydrocarbons (from the oil) and oxygen from the air produces carbon dioxide (CO2), water vapor (H2O), and a significant amount of heat energy.

The heat energy generated during combustion is released as thermal energy. This heat can be harnessed and used for various purposes, such as heating buildings, generating steam for industrial processes, or producing electricity in power plants.

After combustion, the resulting gases, including carbon dioxide and water vapor, are expelled from the combustion chamber as exhaust. Depending on the combustion system, there may be additional steps to filter or treat the exhaust gases to reduce emissions and environmental impact.

Using the Heat Generated from a Waste Oil Burner or Boiler

The heat generated from a waste oil burner can be used for various purposes, such as space heating, hot water production, or process heating in industrial applications. Here are some common applications for utilizing the heat produced by a waste oil burner:

- Space Heating: The most common use of waste oil burners is for space heating. The heat generated can be distributed through radiators, forced-air systems, or radiant floor heating to warm buildings. It’s a cost-effective way to provide heat, especially in large commercial or industrial spaces.

- Hot Water Production: Waste oil burners can also be used to produce hot water for domestic or industrial purposes. They can be integrated into water heating systems to provide a continuous supply of hot water for showers, laundry, or industrial processes.

- Process Heating: In industrial applications, waste oil burners can provide heat for various processes, such as drying, curing, or melting. This can be especially beneficial in manufacturing facilities where heat is needed for specific production processes.

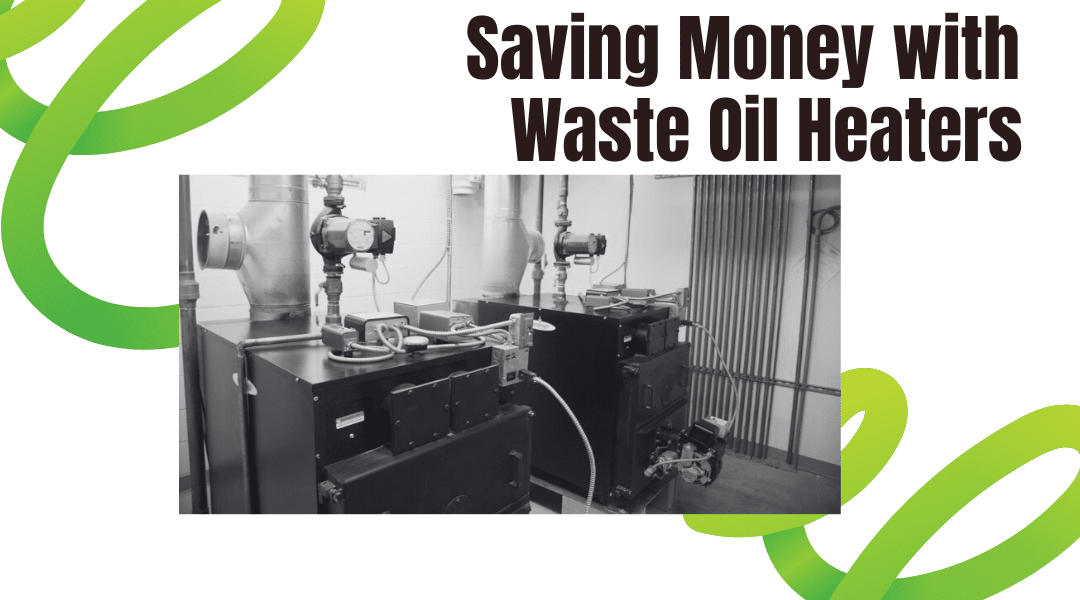

- Boiler Systems: Waste oil burners can be integrated into boiler systems to generate steam or hot water, which can be used for a wide range of applications, including heating, power generation, and industrial processes.

- Greenhouses: Waste oil burners can be used in greenhouses to maintain optimal growing conditions, especially during colder months. They provide both heat and carbon dioxide (CO2) enrichment for plant growth.

Choosing a Waste Oil Burner or Boiler

Choosing a good waste oil heater involves several considerations to ensure you select a reliable and efficient unit that meets your heating needs while adhering to safety and environmental regulations.

Begin with opting for a waste oil heater from a reputable manufacturer with a history of producing reliable and safe equipment. Most UOMA Members, like EnergyLogic, will help you calculate the heating capacity (measured in BTUs or kW) required for your space or application. Additionally, a reputable manufacturer, like EnergyLogic, will offer waste oil heaters with high combustion efficiency ratings, broader fuel compatibilities, enhanced safety features, easy maintenance, custom designs, and extended warranties.

If you are uncertain about your specific requirements or the best waste oil heater for your situation, consider consulting with our experts in waste oil combustion systems. We are here to help you find the best solution to fit your needs.