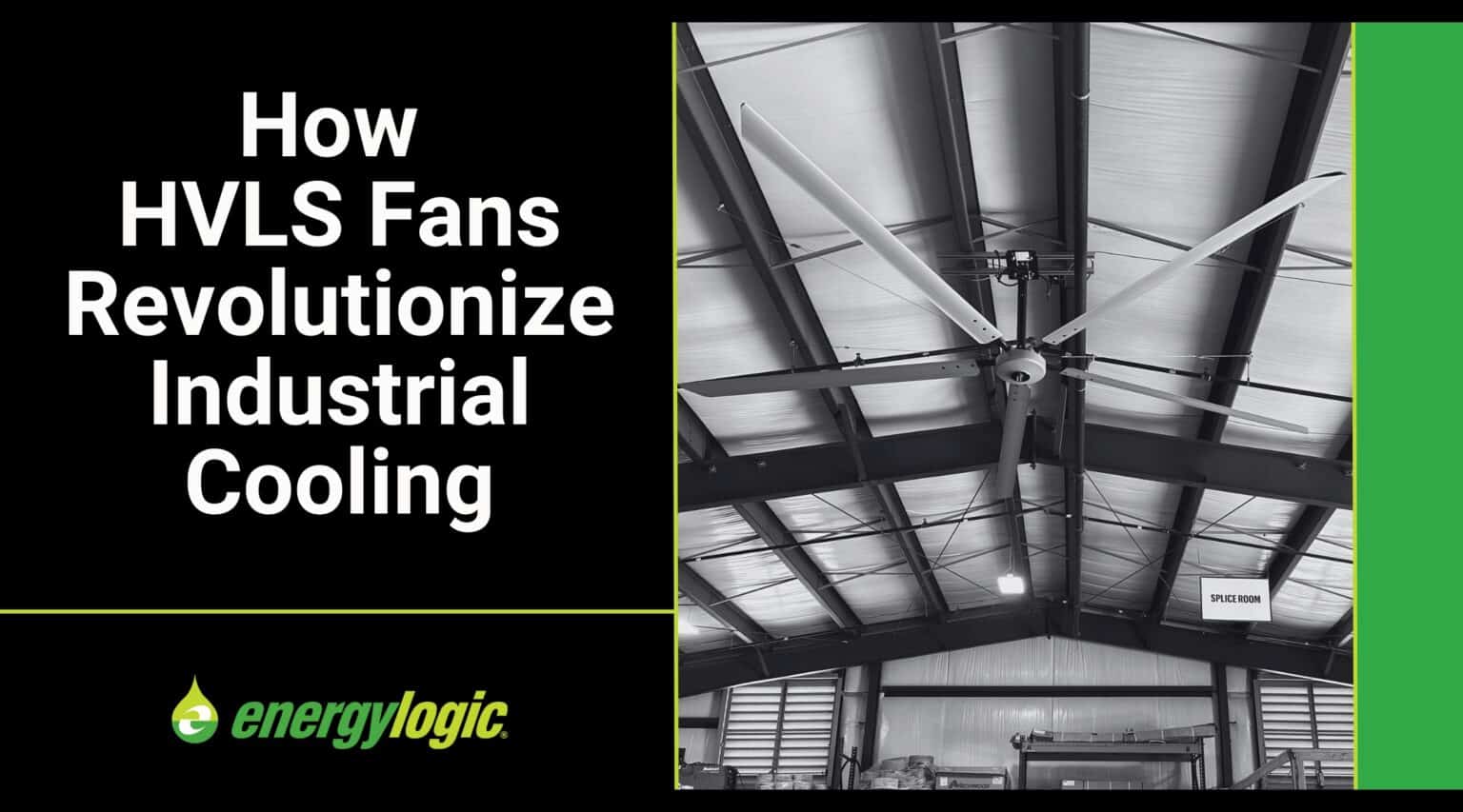

How HVLS Fans Improve Industrial Cooling and Efficiency

Some of the biggest facilities, such as manufacturing plants, warehouses, and large industrial spaces, face unique cooling challenges, no matter the industry. With vast square footage, high ceilings, and significant heat generation from machinery, maintaining a comfortable and efficient working environment can be difficult. Especially in light of some of the hottest summers on record in recent years.

Most often, these large facilities are only equipped with traditional HVAC systems which struggle to distribute air evenly, leading to hot spots, increased energy consumption, and decreased worker productivity. You are also jeopardizing products and livestock without proper cooling solutions in place. Luckily, there is a cost-effective and efficient solution to leverage existing systems, industrial fans.

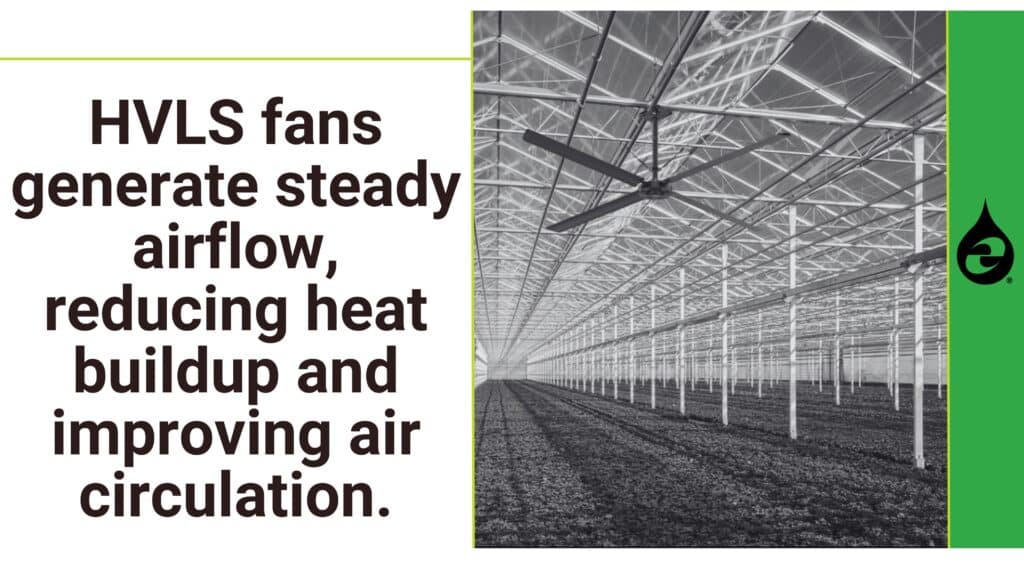

The Role of HVLS Fans in Industrial Cooling

High-Volume, Low-Speed (HVLS) fans are designed to address these cooling inefficiencies by circulating large volumes of air at a slow speed. Unlike small, high-speed fans that create turbulence, HVLS fans generate a steady, gentle airflow that effectively reduces heat buildup and improves overall air circulation. Industrial fans are the perfect complement to large spaces and existing systems because they come in a variety of sizes to fit the space exactly, and are much quieter than small, high-speed fans.

Key Benefits of HVLS Fans for Industrial Cooling

1. Enhanced Air Circulation

HVLS fans create a continuous airflow pattern that moves warm air away from workstations and machinery. This eliminates stagnant air pockets, promoting uniform temperatures throughout the facility. The wide blades were designed using airfoil technology which generates lift and thrust to create a downward column of air, moving large volumes of air quietly.

2. Temperature Reduction and Thermal Comfort

While HVLS fans do not lower air temperature directly, they provide a cooling effect by increasing air movement. This can make a space feel up to 10 degrees cooler, enhancing worker comfort and reducing heat-related fatigue. This is why they are a great addition to existing systems. With an HVLS fan, HVAC systems do not have to work as hard to cool the space, saving you money on your energy bills and also making your HVAC system last longer.

3. Energy Efficiency and Cost Savings

HVLS fans work in conjunction with existing HVAC systems to optimize cooling efficiency. This is why they are a great addition to existing systems. With an HVLS fan, HVAC systems do not have to work as hard to cool the space, saving you money on your energy bills—sometimes up to 30% in cooling costs and also help your HVAC system last longer.

4. Improved Air Quality

Beyond temperature regulation, HVLS fans help disperse airborne contaminants, dust, and fumes, creating a healthier work environment. This is especially beneficial in industries where air quality is a concern.

5. Moisture and Condensation Control

Excess humidity and condensation can lead to equipment malfunctions and product damage. HVLS fans help regulate moisture levels by maintaining consistent airflow, reducing condensation-related issues.

Choosing the Right HVLS Fan for Your Facility

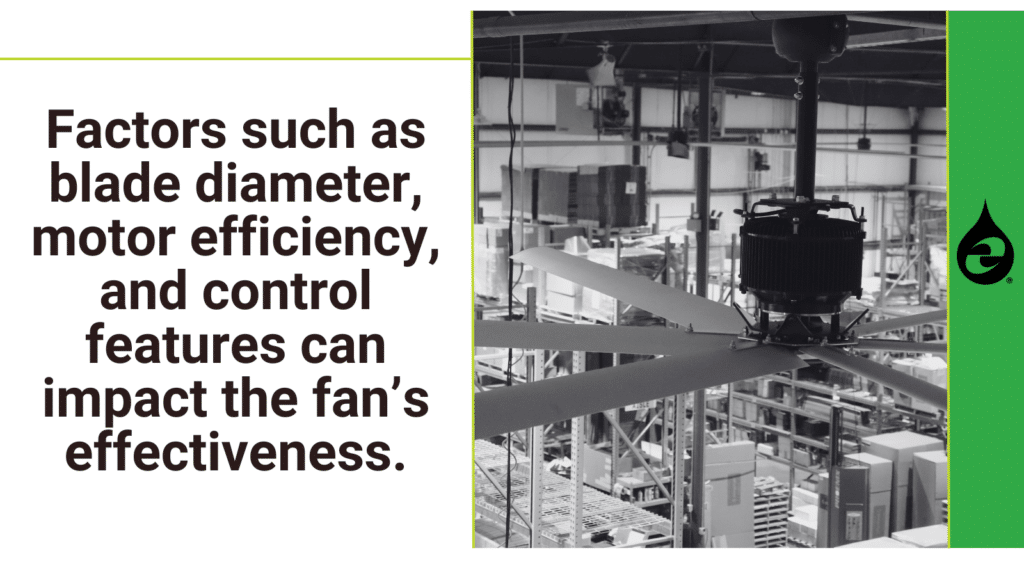

When selecting an HVLS fan, consider the size of your space, ceiling height, and specific cooling needs. Factors such as blade diameter, motor efficiency, and control features can impact the fan’s effectiveness. Many industrial facilities benefit from integrating smart control systems that allow for automated adjustments based on temperature and occupancy.

HVLS fans are a game-changer for industrial cooling. By improving air circulation, enhancing comfort, and reducing energy costs, they provide a cost-effective solution to managing large-scale temperature challenges. Whether used alone or alongside HVAC systems, HVLS fans help create a safer, more efficient workplace while promoting sustainability.

For businesses looking to improve industrial cooling and energy efficiency, investing in HVLS fan technology is a practical and money saving choice.