Choosing the right industrial fan is pivotal for maintaining a comfortable, safe, and efficient work environment. Industrial fans play a crucial role in ventilating spaces, controlling temperatures, and removing impurities from the air. Making an informed decision requires considering several factors such as the specific needs of your business, environmental conditions, and budget. This article provides insights and tips to help you select the perfect industrial fan to meet your business requirements.

Assessing Business Requirements

Understanding your business’s specific fan needs is paramount. Different industries necessitate different kinds of fans.

For example, food processing units might require stainless steel fans to meet sanitary standards, while warehouses might require multiple high-volume, low-speed (HVLS) fans to cover larger areas and move air efficiently. In other cases, you might be on the lookout for a large, portable fan for events or smaller industrial spaces.

Determine whether the fan is required for ventilation, cooling, or exhausting purposes and assess the volume and type of air contaminants involved. This assessment aids in narrowing down the list of suitable industrial fans.

Outlining the Environmental Conditions of the Space

The external environment and internal operating conditions for the space are key factors for selecting a fan that will operate effectively and ensure a long lifespan. Consider the climate, temperature, humidity, and altitude when selecting a fan. High temperatures and corrosive environments necessitate fans constructed with durable, corrosion-resistant materials. A clear understanding of environmental conditions means your fan will be able to ensure the safety of your product inventory, create a comfortable environment for workers and livestock, and prevent environmental problems.

Types of Industrial Fans:

Before making any decision, you need to understand the fan types available for your space. EnergyLogic provides a variety of fan types to make building the perfect cooling or heating system easy and cost effective.

1. HVLS – High-Volume, Low-Speed (HVLS) fans are industrially engineered, ceiling-mounted solutions designed to circulate air and maintain environmental comfort within large-scale spaces. Often seen with diameters spanning from 8 feet to 24 feet, these fans operate at lower speeds, allowing them to gently move massive volumes of air, optimizing efficiency and energy consumption.

- Design: HVLS fans exhibit an aerodynamic design, featuring a set of broad, meticulously crafted blades that capture more air with every revolution. Their structure often incorporates lightweight materials like aluminum, enabling easier installation and seamless operation. The blades are arranged in a specific angle to the hub to create a downward column of air, ensuring uniform air distribution throughout the covered area.

- Performance: HVLS fans operate with superior efficacy, creating a consistent airflow across extensive areas such as warehouses, manufacturing units, agricultural setups, and commercial venues. By manipulating air circulation, they balance the internal climate, mitigating heat stress and enhancing comfort for occupants. They can significantly reduce energy consumption compared to traditional high-speed fans due to their lower RPM (Revolutions Per Minute) and optimized air displacement capabilities.

2. Overhead Fans – Industrial overhead fans are powerful air circulation systems specifically designed to operate in large-scale industrial environments. Suspended from the ceiling, these fans play a crucial role in maintaining air quality and temperature, essential for both equipment efficiency and workforce productivity in settings like warehouses, manufacturing units, and assembly lines.

- Design: Industrial overhead fans boast robust and durable designs to withstand the rigorous demands of industrial applications. Typically constructed from high-grade materials like stainless steel or reinforced aluminum, these fans feature dynamic blade configurations, optimized for maximum air displacement and circulation. The compact, ceiling-mounted design ensures minimal interference with floor-level operations, making them ideal for spaces with limited floor availability.

- Performance: These fans are meticulously engineered to deliver optimal airflow, effectively circulating air across extensive areas and height variations, ensuring uniform temperature and enhanced air quality. They operate at varying speeds, allowing for adjustable airflow. Their high-efficiency motors are designed to consume minimal energy while providing maximum output, supporting eco-friendly and cost-effective operation.

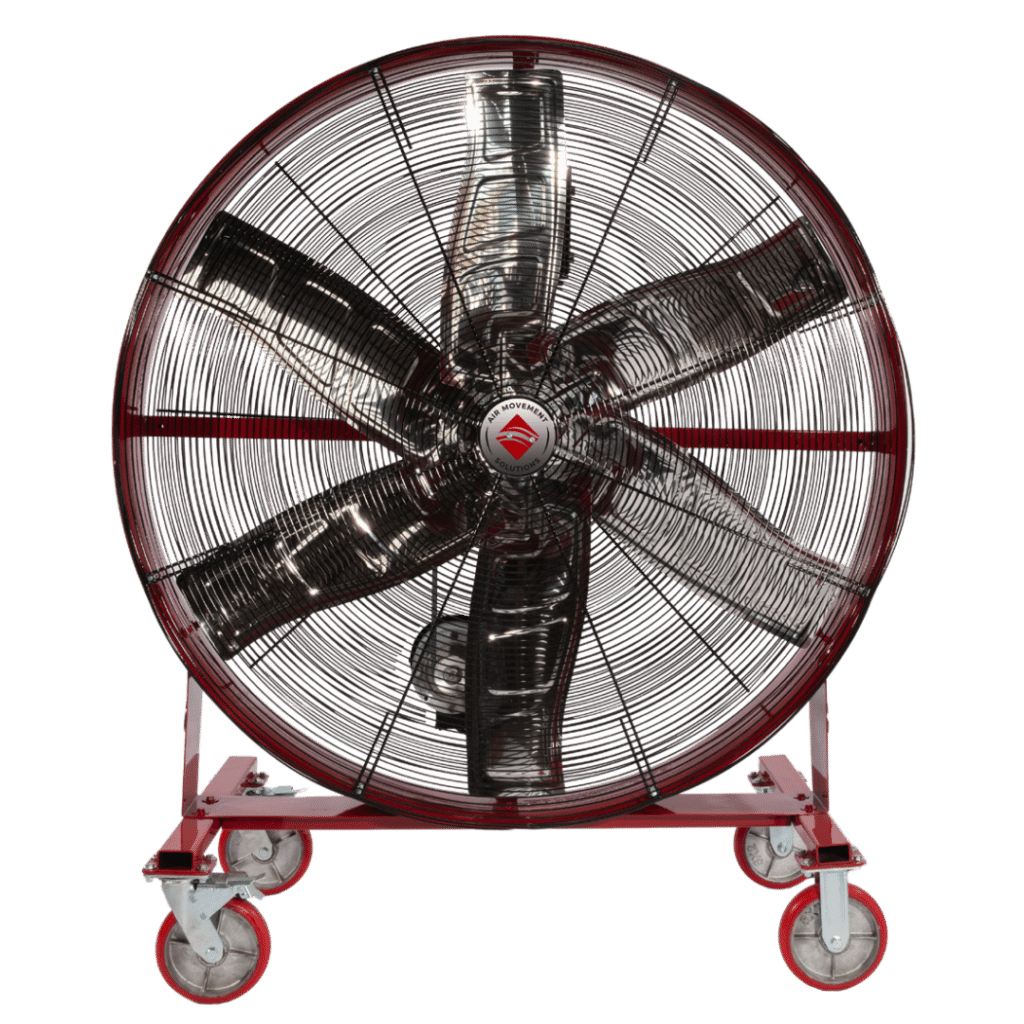

3. Portable Fans – Portable industrial fans are dynamic, versatile air-circulation devices designed for adaptability and efficiency in diverse industrial environments. These fans are characterized by their mobility, allowing for easy relocation to target specific areas in need of enhanced air movement. They are crucial for maintaining air quality, cooling machinery, and providing a comfortable working environment, especially in industrial settings where fixed ventilation may be inadequate.

- Design: Constructed to endure the rigors of industrial applications, portable industrial fans feature rugged designs, usually incorporating durable materials like reinforced steel or high-grade plastics. These fans often have robust wheels and handles, facilitating effortless transportation and positioning. They come in various sizes and configurations, including pedestal, blower, and drum types, each designed to address different air circulation needs.

- Performance: Portable industrial fans deliver powerful airflow, capable of rapidly circulating air in high-volume spaces, and they are engineered for high-performance efficiency, providing maximum airflow with minimal energy consumption. Many models offer adjustable speed settings, allowing users to control the airflow intensity according to specific requirements. Their design ensures quiet operation, reducing noise pollution in the workplace.

Key Considerations to Keep in Mind When Selecting the Right Industrial Fan

Performance

Performance parameters such as airflow rate, pressure, efficiency, and power consumption are critical. Fans with higher efficiency and lower power consumption are preferable. Choose a fan with adequate airflow to ensure proper ventilation or cooling, considering the space’s size and layout.

Noise Level

Industrial fans can generate substantial noise, affecting worker comfort and safety. Selecting fans designed for lower noise levels or installing noise reduction measures can mitigate these issues. Consider fans with aerodynamic blades and noise dampening materials to maintain a conducive working environment.

Energy Efficiency

An energy-efficient fan can significantly reduce operational costs. Evaluate the fan’s energy consumption and consider models with energy-efficient motors and variable speed drives. Ensure your fan has been rated to provide better energy savings and is environmentally friendly.

Durability and Maintenance

Select fans constructed with high-quality materials and coatings to endure harsh industrial conditions. A fan’s durability minimizes maintenance requirements and operational downtime. Opt for fans with features that facilitate easy maintenance, such as self-cleaning blades and easily accessible components.

Safety and Compliance

Ensure the chosen fan complies with industry standards and local regulations. Fans should have safety guards and other features to prevent accidents. Compliance with standards like ISO and OSHA guarantees the reliability and safety of the industrial fan.

While it is tempting to opt for cheaper models, investing in a high-quality, durable, and energy-efficient fan can yield long-term savings. Evaluate the Total Cost of Ownership (TCO), which includes purchase price, installation costs, operating costs, and maintenance expenses, to make an informed decision.

Customization Options

Some manufacturers offer customization options to meet specific business requirements. Custom features like special coatings, filters, or controls can enhance the fan’s performance, longevity, and suitability to your business needs.

Selecting the perfect industrial fan is a multifaceted decision involving a careful assessment of business needs, environmental conditions, and fan specifications. By considering the type, performance, noise level, energy efficiency, durability, safety, budget, and customization options, businesses can ensure they select a fan that aligns perfectly with their requirements and environmental conditions. A wisely chosen industrial fan not only enhances workplace comfort and safety but also optimizes operational efficiency and minimizes long-term costs.