Case Study: Addressing a Client’s Fuel Management Issues

At EnergyLogic, our customers specialize in many industries: automotive, transportation, industrial, commercial, agriculture, and more. Therefore, they often come to us with vastly different infrastructure, heating, and cooling needs. Like the unique challenge Wingfoot Commercial Tire (Goodyear Commercial Tire & Service Centers) had with their waste oil fuel management system.

The Challenge: An Inefficient Waste Oil Storage Tank

Onsite, our customer stored waste oil in an exceptionally tall tank. For storage purposes, the design was functional and convenient. However, the storage tank configuration hindered the process of pumping fuel into the heating system. High-vacuum issues within the tank prevented the fuel pump from doing its job efficiently. As a result, the waste oil burning system wasn’t performing as Wingfoot expected.

To resolve the challenge, our engineers and designers developed a custom fuel management system that optimized our customer’s setup. The project involved strategically placing pumping power where it would work most effectively. Additionally, we extended the range and reliability of the heating system.

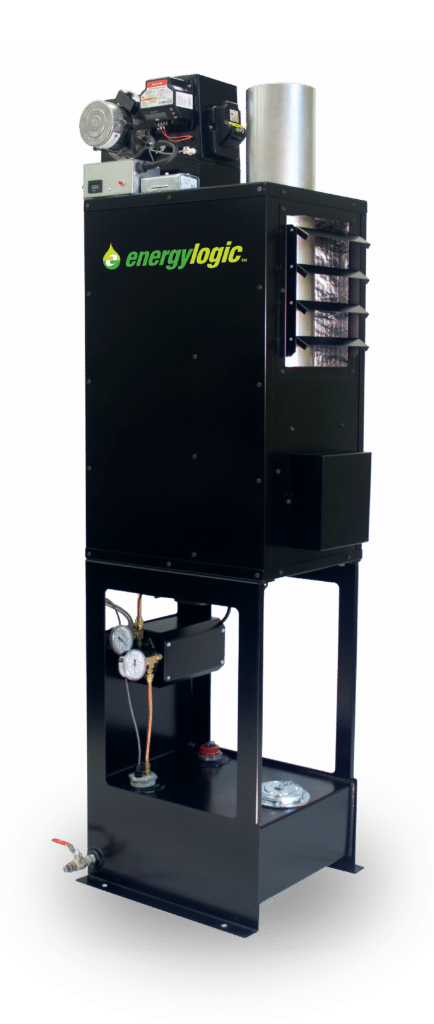

The end result was integrated into our single-unit gravity feed system: the EngergyLogic GFS-Solo. This proprietary system is designed to optimize the flow of fuel leading to improved performance and reliability. Now, the customer’s main tank feeds into the gravity feed system for consistent, clean-burning waste oil heat. The project resulted in additional benefits as well. Wingfoot now spends less time maintaining the system, and they achieve better, more reliable, heat output.

Learn More About Our Gravity Feed Systems

Today, we offer all our customers single-unit and multi-unit gravity feed systems to improve heating efficiency and output. Tanks mounted inside the building supply waste oil continuously while a transfer pump connects the gravity feed tank to the main supply tank. Additionally, the systems include display interfaces with real-time information regarding system performance. Then, to keep the entire system primed with fuel, the product includes smart shutoff systems connected to float switches inside both tanks.

EnergyLogic’s Approach to Fuel Management System Challenges

Some waste oil heater manufacturers provide customers with a product but little support beyond the point of purchase. At EnergyLogic, we’re committed to building long-lasting relationships. We aim to be our customers’ go-to resource for energy-efficient comfort solutions, including waste oil heating, large commercial/industrial HVLS fans, waste oil tanks, and fuel management systems. We provide end-to-end support, so our customers feel 100% confident in their investments at the end of the day.

In this application study, we developed a comprehensive fuel management system that gives the Wingfoot team peace of mind. With an extended fuel management range and improved reliability, the provided solution has improved the overall working experience at Wingfoot. This gravity feed system development project serves as an example of EnergyLogic’s approach to business. We always look for the simplest and most effective solution to each of our customer’s demands. Additionally, we always offer access to our support personnel long after the point of purchase. Combined, these elements contribute to a great customer experience and more efficient solutions.