Case Study: CSX’s Infrastructure and Fuel Challenges

The CSX Corporation is one of the nation’s leading transportation suppliers with a strong focus on rail and intermodal transport. The business produces a significant amount of waste oil during daily business operations. EnergyLogic’s partnership with the company spans more than 15 years and a variety of custom solutions projects. Each project we’ve embarked on with CSX has allowed us to further refine and improve our products. In the following case study, we outline some of the challenges we’ve faced, how we’ve enhanced our services as a result, and how that’s impacted our client’s business.

Challenge No. 1: Quality Issues With Fuel Oils

Energy Logic’s baseline waste oil heating systems accept a range of oils, including synthetic oils (up to 90 weight). Unfortunately, most waste oil burners on the market today cannot support burning railroad oil because of its quality issues. Without the ability to burn railroad waste oil in their EnergyLogic system, CSX would have lost a major fuel supply. When the company’s team contacted us, we stepped in with a solution.

To enable the business to burn railroad and motor oil within the system, our engineers developed a custom design. Additionally, a specific maintenance program was incorporated to eliminate quality control issues. We optimized the system to successfully perform while running on CSX railroad oil.

Today, the business maintains systems that effectively burn railroad oil, giving CSX access to an increased fuel supply. This project served as one of the first custom solutions we provided for CSX.

Challenge No. 2: Problems With Existing Heat Exchange Infrastructure

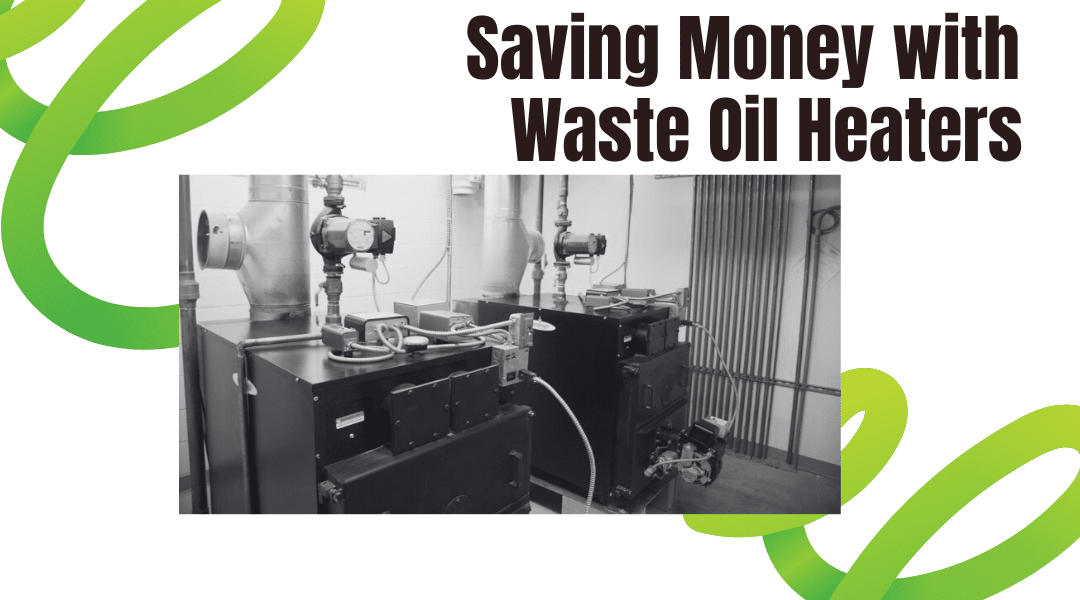

Many of our customers want to tie their waste oil heating system into an existing HVAC system. At the beginning of the project, CSX experienced difficulty cleaning its existing commercial heat exchangers, which led to structural failures. Instead of investing in another conventional heat exchanger that might suffer similar problems, the team at CSX called EnergyLogic.

To prevent future problems with heat exchangers, we designed a custom heat exchanger. We also provided CSX with a field replacement, a modified burner platform, an optimized heat exchanger array, and better access to the combustion chamber.

With an updated, customized heat exchange system, our customer now enjoys improved reliability, better performance, and simplified maintenance routines.

Challenge No. 3: Fuel Management Inefficiency

For any waste-oil-burning system to work efficiently, it needs access to a steady source of fuel. In single structure applications, customers can rely on one fuel tank to house all waste oil. However, in multi-structure applications, fuel management gets tricky. Like many transportation businesses, CSX relies on a network of sites to maintain business operations. Consequently, the company was maintaining an excess of waste oil in one location – but not enough at an adjacent location. The latter site experienced inconsistent heat output as a result.

The team at EnergyLogic developed a custom fuel management system, using existing infrastructure, to carry fuel between collection sites as needed. We augmented the system using our proprietary, automated fuel delivery systems for consistent output over time.

As a result of these optimizations, employees now enjoy reliable, comfortable temperature levels. Additionally, CSX does not need to rely on traditional heating methods in the secondary location – which translates to cost savings.

EnergyLogic’s Approach to CSX’s Challenges

Our team looks at system support from a customer-centric view. If we can use existing infrastructure and resources to improve the experience of using our waste-oil-burning system, we will. But, we’re also not afraid to accept challenges requiring a completely new design. Each new project gives us an opportunity to think about our product from a different angle and provide better overall customer experiences in the future. As a result of these three projects, CSX enjoys more consistent heating, greater energy savings, better performance, and increased fuel supply, among other things.

If you’re interested in learning more about a custom waste oil heating solution, please head over to EnergyLogic.com and fill out the contact us form or give us a call at 1-800-311-8828.