Exploring High Tech Waste Oil Solutions

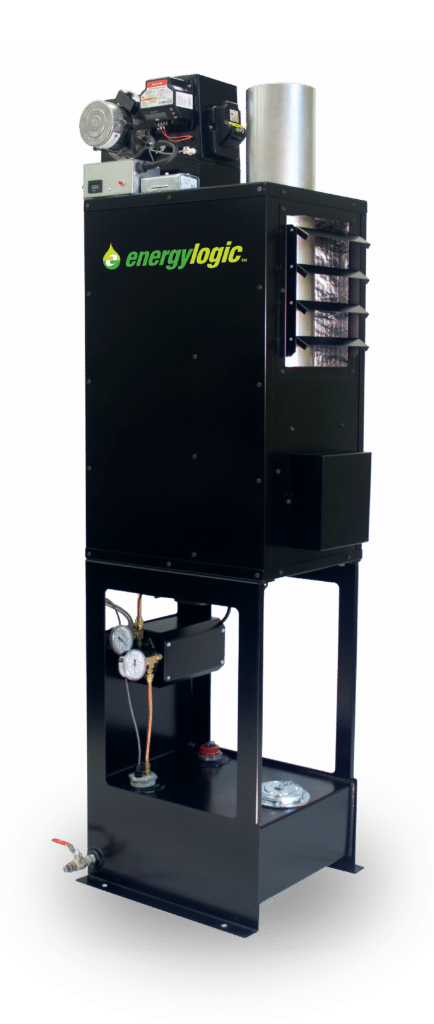

At EnergyLogic, we provide a range of standard and customized solutions for all of our customers, depending on the location, space configuration, and waste oil storage needs. We consider each project on a case-by-case basis. We strive to cut costs, improve efficiencies, and make our customers’ lives easier. This approach enables us to develop new solutions, refine existing ones, and create tailored solutions for better customer experience every day.

As technology progresses and the IoT (Internet of Things) enters more industries, we’ve started exploring ways to simplify and enhance our solutions for streamlined waste-oil system monitoring and controls. Here are some of our most recent technological challenges and the technologies that we have used to address them.

Challenge No. 1: Remote and Mobile/Web-Based Controls

Over the past few years, we’ve noticed an uptick in requests for remote/internet-based waste oil heater controls and more diversity in our existing set of wireless controls. To meet the changing demands of our customer base, our team started involving more tech in our design and development projects.

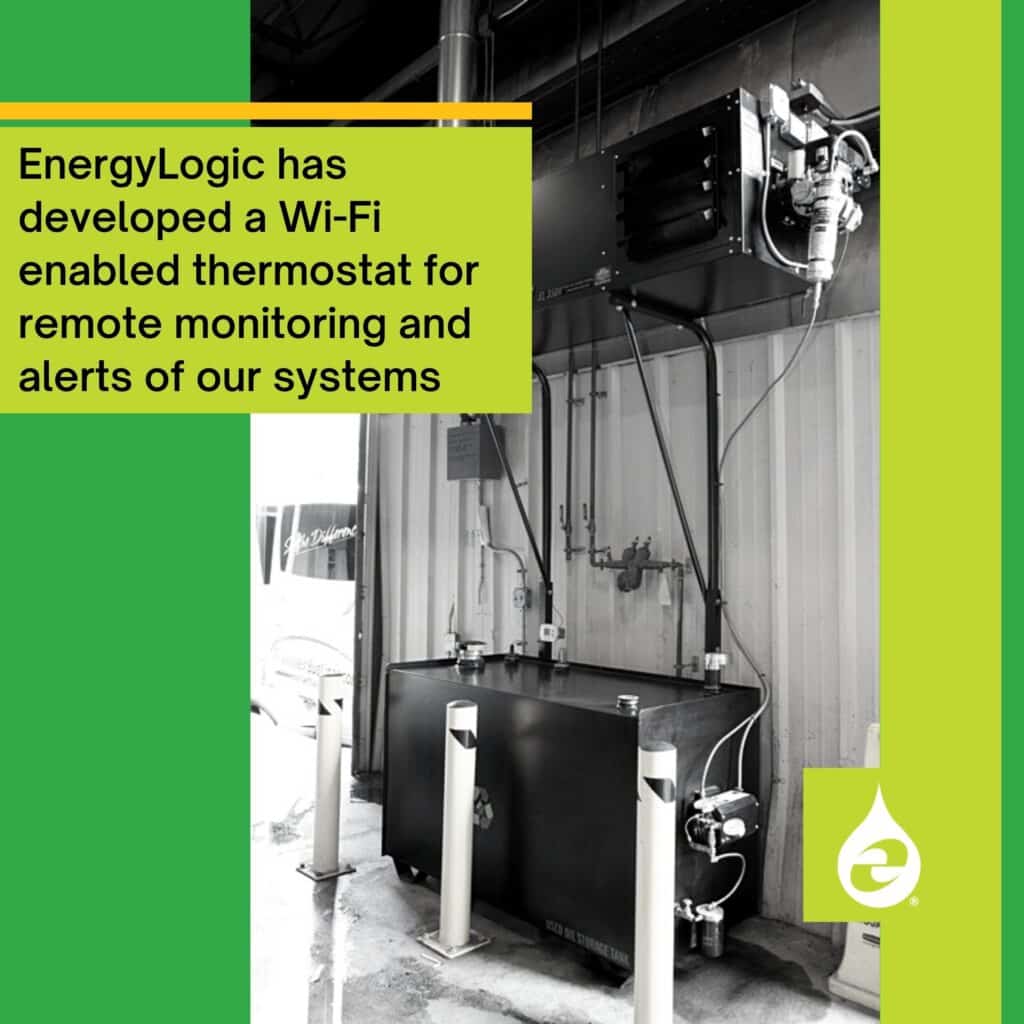

We developed a Wi-Fi enabled thermostat for remote EnergyLogic system controls, monitoring, and alerts. Anywhere our customers can access an internet connection, they can also access their EnergyLogic system. Using the Honeywell Total Connect Comfort web or mobile app, any system owner can securely and quickly access his or her system from anywhere in the world. Set alerts for the app to notify you if the heater loses power or moves beyond set temperature thresholds. A 24V AC-DC transformer from the heater’s existing connection provides reliable power to the thermostat, eliminating batteries for improved communication over time.

The Wi-Fi thermostat gives our customers increased flexibility, control, and peace of mind regarding the everyday functions of their waste oil burning systems. Turn on the heater from your home before you arrive at the shop during the dead of winter. Monitor the functionality of the system if you spend time away from the location. The solution simplifies the EnergyLogic system usage experience.

Challenge No. 2: Knowing More About Waste Oil Supply Levels in Remote Tanks

Not every EnergyLogic system holder spends time around a waste oil burning system on a daily basis. Many system owners travel between locations and run into difficulties manually monitoring tank supply levels on each site. To provide system owners with greater peace of mind, we adopted the SmartBin remote tank monitor.

The straightforward, sensor-based technology of the SmartBin remote tank monitor relays information from each tank back to a database. Our users receive regular email reports of tank levels regardless of their location or proximity to the tank. The SmartBin takes our early warning system to the next level. You can now discover if certain locations’ fuel supplies run low or if an area may run into a surplus in the near future. You can also create a strong waste oil management strategy using routine reports from all remote tanks.

EnergyLogic Moves Forward With Tech

As our customers make recommendations about new functionalities they’d like to see in our products, we listen. With each challenge and development project, EnergyLogic makes the waste oil heating management process a little easier for businesses of all shapes and sizes.

As you search for the right energy-efficient heating and cooling system or look for answers to questions about your existing system, ask us about our recent developments in design and connectivity. We’re focused on delivering the best waste oil burning customer experience in the marketplace.