Farmers’ Almanac has predicted that this year’s winter is going to be cold, wet, and stormy. The only place in the states expected to see higher than-average temperatures are the southern states. Otherwise, from the plains to the Great Lakes and all the way to the west, lower than average temperatures combined with strong storms and wet weather will make for a very cold winter, with the lowest temperatures arriving at the end of January to February.

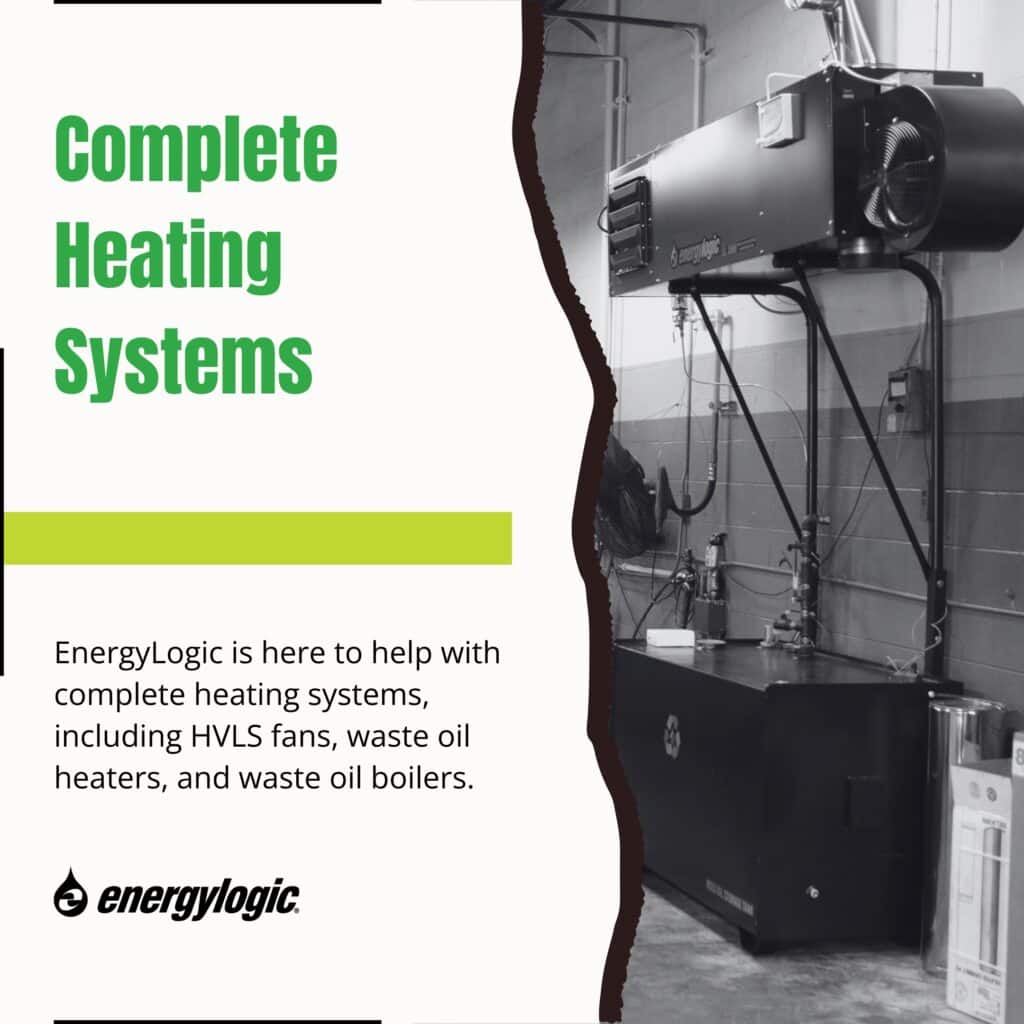

Between the Farmers’ Almanac’s predicting a cold and stormy winter and the estimated increase in natural gas prices, the majority of the country can expect hefty energy bills. Luckily, EnergyLogic is here to help with complete heating systems, including HVLS fans, waste oil heaters, and waste oil boilers. It’s a win-win for any business that generates waste oil and has a space to heat.

Investing in Waste Oil Heating

Winter will be here before we know it, and so will the cold weather. For generators of waste oil, one of the most cost-effective moves you can make this winter is to invest in a waste oil heater or boiler.

The Role of HVLS Fans in Winter

Unlike traditional fans that rely on high velocity to create airflow, High-volume, low-speed (HVLS) fans use their sheer size to distribute air evenly across a wide area, making them highly efficient in large industrial or commercial spaces, such as auto shops, conference centers, warehouses, gyms, and more.

During the winter months, one of the primary challenges in large spaces is uneven heating. Warm air naturally rises to the ceiling, leaving cooler air at the ground level where people work or walk. With an HVLS fan, you can avoid some of the pitfalls of uneven heating this winter. HVLS fans deliver:

· Improved Heat Distribution: HVLS fans gently push the warm air from the ceiling back down to the occupied zones, ensuring a more consistent temperature throughout the entire space. This process, known as destratification, helps eliminate temperature layers that can lead to discomfort and energy waste.

· Increased Energy Efficiency: By continuously circulating air, HVLS fans can reduce the need to run heating systems at full capacity. Heating systems don’t have to work as hard to maintain a steady temperature, which translates to significant energy savings over time.

· Comfort and Productivity: With even heat distribution, employees or occupants experience more comfort, resulting in a better working environment. This is especially important in industries where physical work is required, as temperature fluctuations can affect focus and productivity. Industries with large, open spaces such as manufacturing plants, agricultural barns, gymnasiums, and warehouses will find HVLS fans useful. These fans help create a balanced, energy-efficient environment that is essential for both workers and equipment during cold winter months.

Combining Waste Oil Heaters with HVLS Fans

When waste oil heaters and HVLS fans are used together, they form a powerful combination for winter heating. Waste oil heaters generate consistent heat by burning recycled oil, while HVLS fans ensure that this heat is evenly distributed throughout the space.

· Efficient Heat Circulation: While waste oil heaters produce a concentrated source of warmth, HVLS fans distribute this heat across a large area. With fans, much of the heat from waste oil heaters can be redistributed evenly.

· Reduction in Energy Waste: Traditional heating systems often waste energy trying to keep large spaces warm because they don’t efficiently distribute the heat. By combining HVLS fans with waste oil heaters, you can significantly reduce energy consumption while maintaining optimal warmth. This is particularly important for businesses looking to cut down on utility bills during the winter months.

Balanced Heating in High-ceiling Spaces

Large spaces with high ceilings, such as warehouses or industrial plants, can face major challenges with uneven heating. Waste oil heaters provide a renewable source of heat, and HVLS fans circulate it, ensuring that no energy is wasted. The heat stays where it’s needed most: near the floor where people and equipment are located.

Many businesses that generate waste oil, such as auto repair shops, have successfully combined these systems to heat their spaces efficiently. For instance, an auto garage that used both waste oil heaters and HVLS fans saw a dramatic reduction in heating costs, as the recycled oil powered their heater, while the fan circulated the heat throughout the shop. This not only reduced their waste oil disposal costs but also provided nearly free heating during the winter months.

Financial and Environmental Benefits of Waste Oil Heaters

One of the most significant benefits of waste oil heaters is the potential for cost savings.

· Lower Heating Bills: Waste oil heaters allow businesses to repurpose used oil, effectively turning waste into a heating resource. By using waste oil that would otherwise need to be disposed of, companies reduce fuel costs significantly.

· Optimized Energy Use: With HVLS fans improving heat distribution, heating systems don’t need to run as frequently or at as high a capacity, further reducing energy bills. For producers of waste oil, burning a resource that is already available saves you from having to purchase new resources.

· Longer Equipment Lifespan: Both systems work in tandem to reduce the strain on heating equipment. This can prolong the life of your heating system, lowering maintenance and replacement costs over time.

Environmental Impact

· Reduced Waste: By burning used oil in waste oil heaters, companies can reduce the amount of oil that would typically be discarded. This contributes to a reduction in environmental pollution, as waste oil is often classified as hazardous and spills are toxic to the environment and expensive to clean up.

· Lower Energy Consumption: HVLS fans help reduce energy consumption by optimizing the heat generated, meaning less energy is needed to keep spaces warm. Waste oil heaters do not use additional energy to burn waste oil, meaning you are not paying for natural gas or propane to heat your space. Over time, this can lead to a smaller carbon footprint for your business.

· Fewer Emissions: Waste oil heaters can also help reduce emissions compared to traditional fossil fuel heaters. The combination of these systems allows businesses to meet both their heating needs and sustainability goals without compromise.

Since it’s still October, you have time to plan for the winter weather by purchasing a waste oil heater or boiler and getting an HVLS fan set up. For more information, call the EnergyLogic team today!